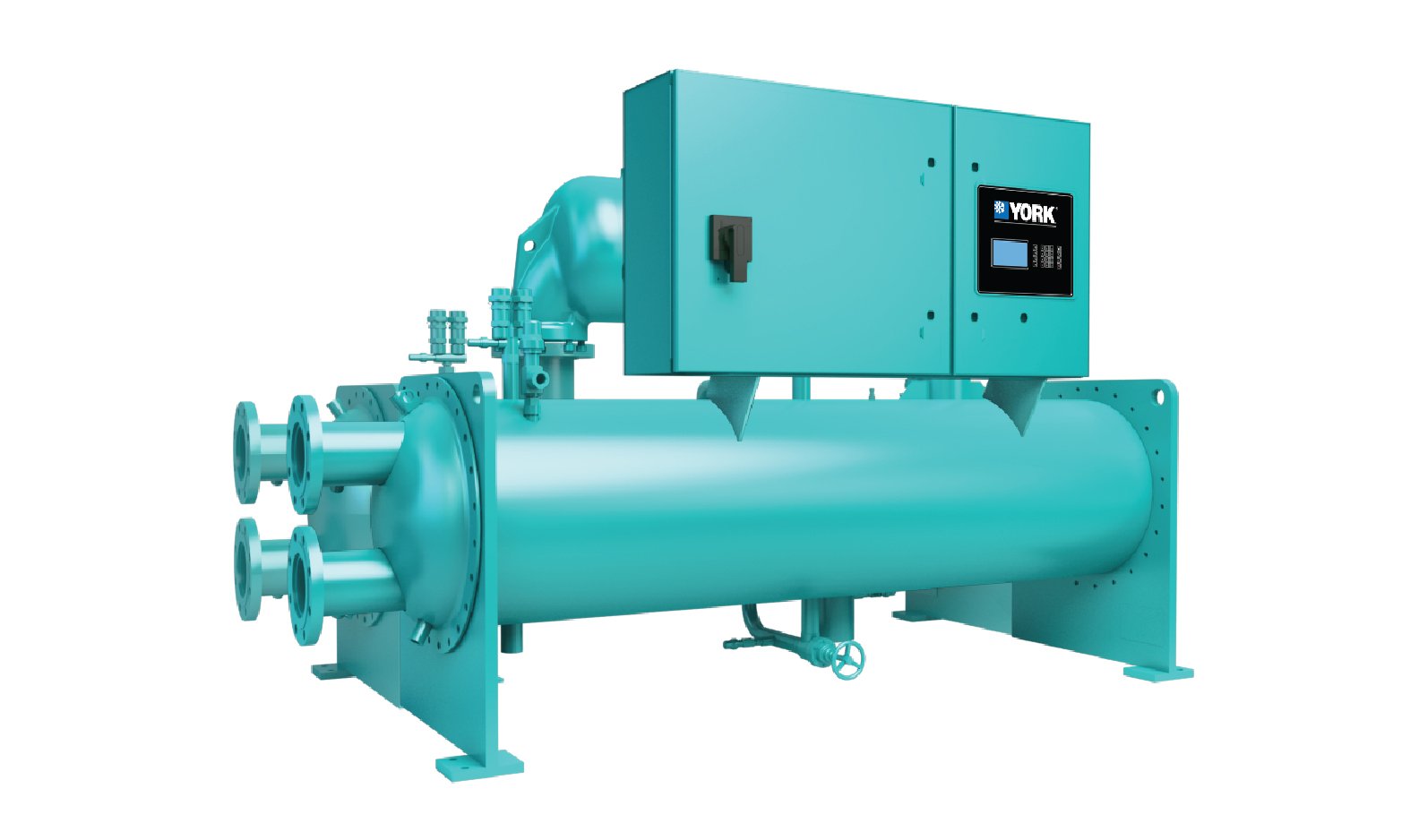

Water Cooled Chillers

A bag filter, also known as a fabric filter or baghouse, is an air pollution control device designed to remove particulate matter (dust, particulates, and solid particles) from industrial gas streams. Bag filters are widely used in a variety of industries to improve air quality and ensure compliance with environmental regulations. They are particularly effective for capturing fine particles and have a straightforward and reliable design. Here's a description of the key components and operation of a bag filter:

Components of a Bag Filter:

- Housing: The bag filter is housed in a container or chamber that accommodates the filter bags and provides the necessary structural support.

- Filter Bags: The heart of the bag filter system, filter bags are cylindrical fabric tubes made of various materials (such as woven or felted fabric) that capture and retain particulate matter from the gas stream. These bags are suspended inside the housing.

- Inlet/Outlet Ducts: The industrial gas stream enters the bag filter through an inlet duct and exits through an outlet duct.

- Cleaning Mechanism: Bag filters often have a cleaning mechanism to remove accumulated dust from the surface of the filter bags. Common cleaning methods include reverse air, pulse-jet, or mechanical shaking.

Operation of a Bag Filter:

- High Efficiency: Bag filters are highly efficient at capturing fine particulate matter, making them effective in improving air quality.

- Versatility: They can be used in various industrial applications to control dust emissions and particulate matter.

- Economical: Bag filters offer cost-effective solutions for air pollution control, given their efficient operation and relatively low maintenance requirements.

- Low Pressure Drop: They typically have a low pressure drop, which minimizes energy consumption in the gas-handling system.

- Scalability: Bag filters can be easily scaled up or down to meet specific industrial needs.

Bag filters are commonly used in industries such as cement manufacturing, power generation, food processing, pharmaceuticals, metals production, woodworking, and many more where the control of particulate emissions is critical for environmental compliance and workplace safety.